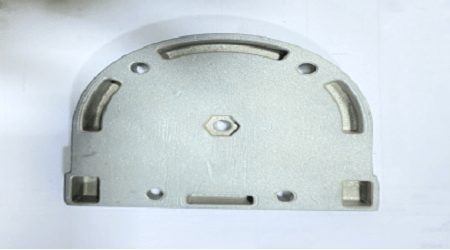

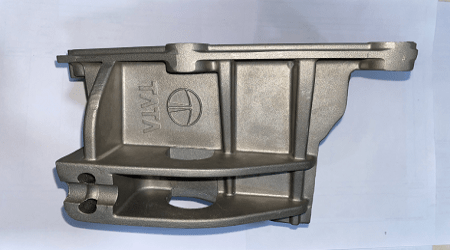

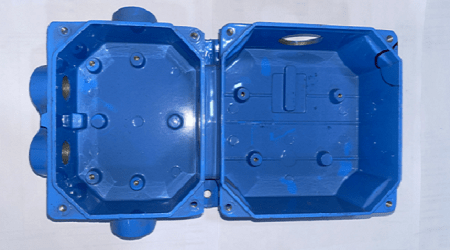

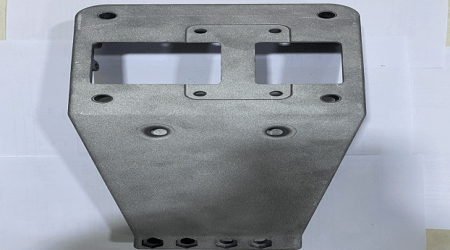

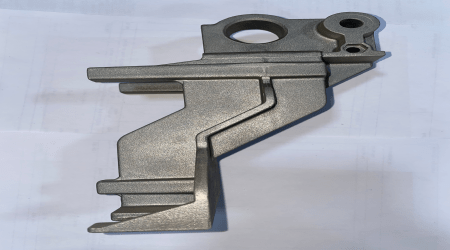

Manufacturing of Aluminium & Zinc Auto Components

Incorporated in 2019, GEEKAY DIECASTING offers you the facility of high pressure die casting using different metals and the resultant products maintain the quality standards set.

The division has installed 2 high pressure die casting YEZUMI machines ranging 180T to 300T and each machine has a holding furnace and Jet cooling facilities. All the process parameters are being controlled and recorded through real time controllers. The technology used ensures high volume along with the dimensional accuracy and surface finish which require minimum machining, thereby offering cost advantage to the customers. At Geekay Diecasting we cast ideas into components.

Our Portfolio

Our Infrastructure

LOOKING FOR A RELIABLE SUPPLIER?

At Geekay Diecasting, we aim to build long-term partnerships with our clients in order to ensure a world-class, integrated supply chain. We strive to consistently meet extremely high standards for quality, delivery, cost and customer satisfaction for our clients.

Contact Us